Keep this story going! Share below!

Fabdesign is in the business of textile science. Traditionally, textiles are produced through laborious techniques, such as cut and sew, that produce considerable waste and have many limitations. The founders, Connie and Bruce Huffa, help clients produce state of the art products that do not require fabric cutting, use minimal sewing, and produce little to no waste. By using flat knitting technology (knitting in sheets instead of a circle), Fabdesigns is able to knit to shape and knit 3-dimensionally. This technique has allowed the company to reduce waste, improve productivity, and spur innovation throughout the manufacturing industry.

Knitting, as a technology, has always been inherently minimal waste--you knit the exact shapes you want, as opposed to cutting shapes out of a sheet of fabric, leaving scraps behind. Connie and Bruce--not only lifelong knitters, but also two people incredibly knowledgeable about the waste and impact of cut and sew techniques--have dedicated their careers to pushing that technology past its boundaries, blazing new trails as they make possible what was once impossible. Before the advent of computerized and motorized flat-knit machines, it was financially impractical to knit to shape and 3D knit; it simply took too much time, compared to cut and sew techniques, and was therefore much more expensive. Now, with the advantage of computerized and motorized machines coupled with their expertise in knitting and flat-knit programming, the Huffas help their clients realize reductions in waste and environmental impact and a decrease in production costs resulting from increased efficiency in the knitting process and transportation savings from reduced product weights.

Crucially, beyond the advanced technology of today’s flat knit machines, Connie and Bruce are the key components of Fabdesigns innovation: they often make the impossible possible with their willingness to try what hasn’t been done. Often, clients will come to them with concepts, but without the ability to execute the idea. The Huffas approach each project with a commitment to solving the puzzle, and adding in some of their own innovations along the way--like designing a shoe upper that is completely recyclable (the original design for the Nike FlyKnit), or even pushing further and designing a Cradle to Cradle (a term championed by green designer William McDonough and refers to an approach to designing intelligent products that take into account the entire life cycle of the product) certified product composed of yarn made from recycled ocean waste.

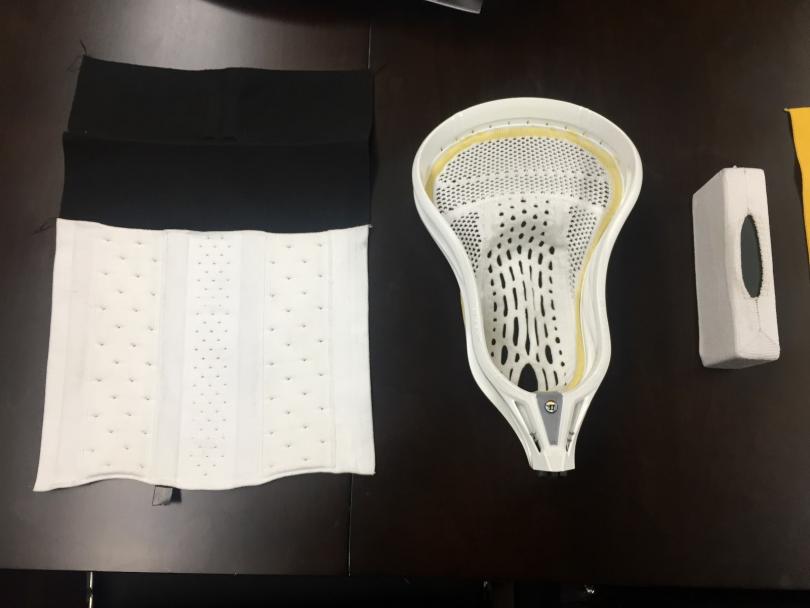

Some of Fabdesigns’ most noteworthy projects include the Nike Flyknit shoe and Warrior Warp lacrosse stick head. The Nike Flyknit shoe reduces waste by over 60%, compared to traditional cut-and-sew production practices. The Warrior Warp head is poised to eliminate the need for players to rely on professional stringers to ensure that their stick heads are ready for games. Using knitting technology will also reduce the number of whistles blown for players to step to the sideline and address loose strings from stick heads. Games will be smoother, and players will be able to leave the worry of strings behind as they focus on the sport. Because every stitch is knitted to specification, there is zero-waste in the manufacturing process. Currently, the Huffas are pursuing innovations in technical textiles: exploring the intersection of technology and textiles in medical devices and performance aerospace components.

Chatting with Connie and Bruce in their space in the Santa Monica Mountains, they’re connection to the environment was apparent. They operate their business out of a nondescript building--which probably used to be a barn on a quaint ranch just outside of Malibu. (They serendipitously came upon the opportunity to lease the space after a conversation with the ranch owner, in which they discovered their mutual concern about environmental impact.) So it wasn’t at all surprising that, when asked when it was they became passionate about reducing waste through innovative knitting techniques, they shrugged their shoulders as if they had just been asked when it was they started breathing air: zero waste has always been a value. That being said, they committed to driving their value of low impact through their business after having seen the immense waste produced by traditional cut and sew techniques.

The capabilities of flat knitting machines have serious implications on society and the environment. On the environmental side, the processes Connie and Bruce encourage their clients to use are low to zero waste, can leverage recycled materials such as ocean waste, and even have recyclable potential. This is in stark contrast to the traditional cut and sew practices for knitwear, which is incredibly waste-intensive.

Fabdesigns is ushering in the wave of manufacturing trends to create innovations that allow customers to buy products that meet a specific need (for sports equipment or running shoes), while supporting the principle of zero-waste. Fabdesigns’ leadership via flat knitting machines ensure that bodies of water are kept cleaner and, in turn, living organisms that rely on the waters as their habitat are protected. Additionally, by decreasing waste generated in the production process, Fabdesigns innovations are positively impacting communities in the developing world that disproportionately deal with dead stock (fabric waste resulting from the cut and sew process). Furthermore, the use of flat knitting machines has helped improve the safety of manufacturing environments tremendously. Just as flat knitting machines help keep dead stock out of waste streams around the globe, these machines also spare workers from the dangers of cut and sew manufacturing, like repeatedly cutting fabric patterns, due to built in safeties. In developing countries, the impact of these safer machines will trickle down in poignant ways: women, who are often employed in textile factories, will be less likely to face injury in the workplace, which decreases the risk that physical impairment will stand in the way of securing funds used for critical needs, food, shelter, and health.

Wherever a need for increased efficiency in a textile-related product exists, the Fabdesigns approach can be used to design and manufacture a business solution. Because of the success of two ground-breaking products (the Nike Flyknit shoe and Warrior Warpe lacrosse stick head), the textile manufacturing industry will always be able to point to the Fabdesigns approach as an important reference point for sustainable design. At the same time, businesses will be more equipped to look closely at the products they sell and the visions that are used to match consumer needs in light of the precedent established by knitting technology. Lastly and, arguably most importantly, consumers will encounter a higher level of sophistication, functional efficiencies, and ecologically-minded products that are available for purchase. This expands choice and enhances what consumers can expect from future products within the textile arena.

For consumers, these products represent a radical break in tradition--by owning a product that has built-in efficiencies made possible by knitting technology, the use of recyclable materials, and superior functional capabilities, consumers confirm the market viability of similar breakthroughs that support the Sustainable Development Goals (SDGs). The creation of the FlyKnit and Warrior Head advance sustainability efforts at the level of industry, business, and the consumer. Fabdesigns’ commitment to using cutting-edge technology, the cradle-to-cradle approach, and developing products that meet long-standing needs position their innovations as prime examples of how to meet the SDGs.

The business benefits of Fabdesigns' innovation are many fold. The innovation has directly led to lower production costs for the various companies for whom they've developed patents for while also increasing the quality, reliability and durability of their products. For example, the Nike FlyKnit shoe has estimated to have increased their net income by roughly 40%, which is in large part thanks to the production techniques that Fabdesigns helped Nike develop.

As mentioned, a great example of the potential business benefits is the success of Nike's FlyKnit shoe. The success of Nike’s flyknit shoes has also increased broader consumer demand for products that support the circular economy, which has inspired other companies to begin exploring similar innovative production practices. The World Economic Forum estimates that the fast moving consumer goods could generate $700 billion in annual savings on raw materials alone if more products like the Flyknit enter the space. (https://www.weforum.org/agenda/2016/06/trainers-circular-economy-nike/)

Connie and Bruce remain focused on demonstrating to clients and the world that low-to-zero waste flat knit manufacturing is not only possible, but financially viable. With the capabilities of motorized and computerized flat knit machines, it has become more feasible to knit to shape or knit 3-dimensionally, versus utilizing cut and sew techniques. Importantly, their innovations are what Fabdesigns has built their entire business model around and has helped them remain a pioneer in the sustainable production business for almost 30 years!

As mentioned previously, Fabdesigns helped design the production process behind Nike’s proprietary FlyKnit shoe. This revolutionary way of manufacturing shoes is estimated to reduce waste by over 60% compared to traditional cut-and-sew production practices. Across the apparel industry, most manufacturing processes waste 15% of materials in the production process. To give a sense of the potential scale, a study done by MIT in 2013 estimated that the production of each pair of shoes generates roughly 30 pounds of carbon dioxide emission, “consists of 65 discrete parts … and 360 processing steps”, and that 25 billion pairs of shoes are made annually. (Chu, Jennifer http://news.mit.edu/2013/footwear-carbon-footprint-0522, 2013) In 2016, to mark the fourth anniversary of the FlyKnit shoes, which have seen tremendous commercial success, Nike calculated that this new production technique had reduced nearly 3.5 million pounds of waste and, while they don’t actually calculate the carbon savings from the reduced transportation, it has reduced the number of suppliers to 1, thereby dramatically reducing the number of steps in the typical production process.

In light of this, Fabdesigns, and the outlook it provides for paradigmatic change in an industry commonly associated with business-as-usual, offers society a new way of looking at products that thrive while providing opportunities for regeneration through reduced waste. If consumer goods are expected to offer such a substantial amount of savings on materials alone, there is a strong business case for placing a price on the natural capital benefits of this production technique as more players move towards flat knit manufacturing. This technique also enables companies to reduce their ecological footprint by not only requiring less materials to produce products, but also specifically less virgin material as this innovation derives value and utility from products already in circulation (i.e. using recycled plastic).

Get stories of positive business innovations from around the world delivered right to your inbox.

Connie Huffa, Co-Founder/ Owner