Keep this story going! Share below!

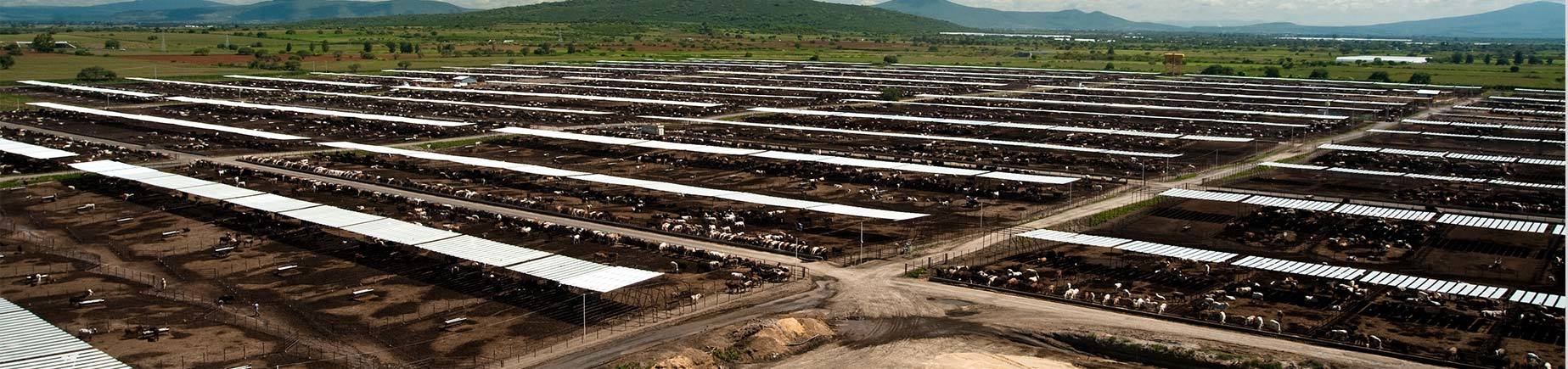

SuKarne produces and commercializes animal protein. SuKarne is the principal meat producer in Mexico. SuKarne holds an average of 550,000 heads of cattle in our feedlots. Those 550 thousand obviously produce manure each day. That inspired SuKarne to create a subsidiary called VioHache which instead of just throwing away the manure and contaminating the environment, instead processes it and converts it into an organic fertilizer. This organic fertilizer allows agricultural producers to grow less contaminated foods due to the control that the fertilizer has. Which ultimately is good for the final consumers because they are eating products with higher quality which improves the health of people. Each year SuKarne’s subsidiary VioHache produces around 550 thousand tons of livestock manure per year.

In 2005 VioHache began collecting the livestock manure from the plants of its parent company SuKarne. VioHache takes the manure to land specifically designed for the production of compost. Then creates batches of five tons each, these batches are processed with high technological machinery that hold large quantities of volume. These machines are self-propelled as well as self-sufficient and can process up to 3000 tons per hour. Inside the machine, each batch is turned around between 20 and 24 times, then we hydrate it and through a thermophilic process we are able to exterminate all the bacteria and small insects that are present in the manure. At the end they get top quality compost with a lot of traceability.

When VioHache hands the compost to the producer it also hands a data sheet that contains, physicochemical parameters of the compost, a certificate that states it is free of phytopathogen, a temperature graph which is reassuring that there are no insects in the compost, it also includes the number of turnarounds the compost received. The company has certificates such as OMRI in the United States, COFEPRIS in Mexico, VioHache is part of the United States Composting Council and also has a certificate to export to Europe, Bioagricert. The clients of VioHache are the top producers in Mexico, of bananas, tomatoes, eggplants, avocadoes etc.. These clients export their fruits and vegetables to different continents including Europe and also sell to very important supermarket chains.

This is what we do, what is the specific innovation?

The traceability of the batches, the specific and according treatment we give to each batch depending on its necessities, we are decreasing the use of fuel, we are bringing down the emission of methane gases to the environment and we are helping fix the carbon inside the soil. We increased productivity in the plants and got the producers to not use as much chemical fertilizers. Which brings safer foods to the tables of families.

The company was born from a need to displace manure, dust control, care for people and the environment, helping the community and reducing the number of inorganic fertilizers.

How does the idea of the project start? "It all starts when a Cuban citizen asked for an interview with a member of the company staff, to look for an alternative in the manure commercialization, because on that time the company has only commercialized not processed manure that was used in order to ensure the producer's plantations nutrients and also its conservation in the long run, since he as a producer and buyer of the product waits for the composting process to take place in their field".

So how does this Cuban citizen change the business’ activities? "Well he taught us how to build of the composting process, how to process manure but not only small amounts of it but make volumes of it in order to ensure economies of scale in the long run. Since that time the business has changed its main activities to the composting process for around 15 or 16 years already, we are the number one in Mexico having all this commercializing processing using the composting procedures, and also we produce own own organic fertilizers, since we as a business count with all the organic certificates that allow us to do it properly".

The impact to environment is less gas methane that it is emitting, which causes pollution and in a long term effect global warming. We are decreasing the hoofmark of carbon in the world. We are having a higher dust control, a better control for smell. Regarding the short term effects, it is causing less expenditure from from producers in chemical fertilizers because it is giving the compost at a lower price due to its scale economies. Which is very attractive for food producers to use organic fertilizers because it creates higher quality products. The people that buy products from our clients will get a healthier life. Also, indirectly we are using less fertilizers with the agriculturists and we are not destroying the soils. Regarding the long term effects, a better income for the company, a minor environmental impact because we have improved the quantity of organic material present in soils. Another impact that we have hard evidence of, is that SuKarne went from loosing revenue from having to throw away the manure into creating profits out of the manure that the company was throwing away.

The innovation, in general, provides additional revenue to the business that in previous years were considered as untapped income. Since now the manure is appropriately used and included in the inorganic fertilizers the business will increase 350k euros in revenue for the whole year, it does not seem that much, however just with this innovative idea they were able to increase revenue from waste that will also help employees and investors in the future.

Without this innovation many employees will now be unemployed, however new staff was included in order to cover the different composting process. Daniel told us that approximately 100 new employees were incorporated in order to ensure the production of this organic fertilizers, and later now he thinks that revenue can increase to 1 to 1,5 million just for this composting process so clearly new jobs are eventually going to be created. “In 5 years, if this successful innovation continues taking place, approximately we will need from 300 to 500 new employees, helping those areas where people are not able to find a job, more specifically in those rural areas” was what Daniel stated.

Finally, investors will be able to gain a lot from this technique since it is just the beginning of the composting organic fertilizers maybe they will be able to invest in the research and development area in order to look for a more sophisticated way to produce manure and therefore increase revenue from this innovation ensuring long- term increase returns for this investors. Overall, the business is going to increase reserves and also help society with new job opportunities.

With the help of this innovation Daniel told us that “soils are going to be treated in a most proper way”. Since the use of organic fertilizers that the business is implementing will help to reduce salt accumulation in different plantations what will produce an overall benefit in a long-term scale. Soil in general will not be compacted that much so plantations will be able to grow more appropriately. Moreover, the implementation of composted fertilizers will also prevent plantations damage all over the market, specially in Mexico where an excessive amount of inorganic fertilizers can be harmful for life on land in general. Daniel stated that “with the use of this innovation producers may be able to increase up to 15% to 20% more their overall plantations than with the use of regular inorganic fertilizers”.

“With the use of inorganic fertilizers, we will ensure sustainability of soils during large periods of time”, Daniel stated. Since this organic innovation will not contain chemicals that are going to kill microorganisms present in soil plantations, these living organisms will prevent soil from erosion and ensure production in the future. Overall, erosion is being controlled and production can increase with the use of this innovation.

Water contamination is an issue taking place around the world nowadays. With the use of organic fertilizers, we will help control this situation. “Overuse of composted fertilizers will not affect ponds or lakes since this instruments lack of chemicals harmful for the environment, that is not the case when inorganic fertilizers are used since residuals end up on rivers killing living organisms.” Summing up, we can clearly observe how this innovation will increase sustainability for society and can be the base of a massive agricultural development.

Get stories of positive business innovations from around the world delivered right to your inbox.

Daniel Alejandro Vizcarra, Sr.

SuKarne produces and commercializes animal protein. SuKarne is the principal meat producer in Mexico with at least 76% of the market. Its chain of production includes more than 100,000 agricultural and livestock providers. Annually it processes more than 1.5 million heads of cattle. SuKarne products are available through 40,000 points of sale and consumption, including retail chains, butchers and a variety of restaurants. SuKarne sells its products in four different continents around the world.