Keep this story going! Share below!

Our home is one of the most beautiful places in the universe. We will always be amazed at what Mother Nature has blessed us with, from volcanoes, rainforests, tropical islands, etc. However, there is one critical responsibility we all have. Whether we are just one individual or an entire corporation – we must all care for our home. While individuals are doing their own part, sustainable companies are doing theirs.

The Ditto Hanger is the first sustainable hanger invented in 2006 by Greenheart Global Inc. It is made from recycled paper fiberboard, making it biodegradable and recyclable. The objective was to develop a more environmentally friendly hanger to replace the plastic hanger. The Ditto Hanger proved that the most beautiful things in life can be sustainable through four initiatives – sustainable cities and communities, responsible consumption and production, building resilient infrastructure, promoting inclusive and sustainable industrialization, and fostering innovation and life on land.

Larry Chernicoff and Gary Barker co-founded an environmentally friendly manufacturing company called GreenHeart Global to design and develop a sustainable product. Mr. Chernicoff's idea was to redesign the wire dry-cleaning hanger after learning that 350 million wire hangers end up in landfills annually. After more research, they discovered that 20 billion plastic hangers are in landfills.

There were several obstacles that Gary faced when developing the sustainable hanger. The first obstacle was the very inexpensive plastic hanger and how they could compete with it. The second was to ensure the factories and materials were certified, and the costs of sourcing and production had to be considered. Then, it was outsourcing the hanger manufacturing overseas since most retail companies use a hanger company called Garments On Hangers (GOH). They buy plastic hangers and import the garments already on the hanger to the United States. Greenheart Global would have to sell and manufacture their hangers overseas to meet the local needs of the vendors. Lastly, they had to educate retailers and consumers about why sustainable hangers should be used rather than plastic. Since no one paid attention to the waste stream of the plastic hanger, no one thought there would be a need for change.

Greenheart Global's main objective was about innovation, to design products that would not end up in a landfill every year and prevent more waste. The company was established to be transparent regarding sustainability and prove that everyday items and beyond can be sustainable.

Founded in 2006 by Gary Barker and Larry Chernicoff, Ditto Hangers was just a green industrial design company. In the beginning, Gary wanted to design something glamorous like a toaster and didn't have an intention to do commodities at all. Although the company started working on a sustainable hanger, they were also working on other products and designs, such as a fiberboard storage system for college dorms, home offices, etc. "With our limited resources and the huge number of hangers going into landfills, we knew we needed to focus on the hangers." At that moment, the company realized that a lot of research needed to be done as "Nobody cares about hangers, nobody knows what they do and what hangers came from. Because there was no other commodity so prevalent, so ubiquitous in our daily lives, and so universally despised. Hanger is a perfect example of bad design and unnecessary waste. "

Ditto Hangers invented technology from the ground up, experimenting with materials such as used tires, pieces of discarded lumber, and plastic with coffee grounds to find the right solution: paper, a material that can be recycled in any part of the world. The motivation was to show that even something as ubiquitous, as low as a product such as a hanger, could be redesigned and engineered to do more than just defy gravity. Unlike regular plastic hangers, the Ditto hanger has many features such as branding, representation of environmental philosophy, QR codes for special promotions, and new collections.

"I told Larry back in 2006 that we started too late. It turned out we started way too soon." In the early 2000s, Ditto Hangers talked to every possible brand in Europe and US. "Apparel businesses would tell us that they knew they'd have to change to a more sustainable hanger someday, but that until their consumer asks them to do it, they wouldn't." It wasn't until around 2020 that global concern over plastic and pollution finally took hold. The plastic ocean gyres and climate change focused the world on single-use plastic. "Suddenly, major clothing companies we had talked to years before were calling us up. Europe was especially interested in our hangers due to the single-use plastic bans there. In 2021 Nexgen Packaging acquired Ditto, and I'm now working with them to bring the Ditto Hanger to scale and push it to new heights."

The company's research estimated that around 25B of plastic hangers are made every year, whereas Ditto Hanger's capacity can now reach only 100M of paper hangers annually. "We were able to conserve natural resources and take responsibility for closing the loop on this wasteful commodity. We don't see designing responsibly as a hurdle or a problem. We see it as an opportunity to create beautiful, intelligent, highly functional products for the Present that respect the future." CEO and founder Gary Barker predicts the appearance of paperhangers in regular stores in about three to four years from now, together with more general attention to plastics waste. "Most of all, we're optimistic about the future and believe the retail industry can and must provide leadership in conserving natural resources, educating the public, and taking responsibility for closing the loop on products. We choose recycled paper over plastic!"

A plastic hanger only does one thing: hang a garment in space. The Ditto Hanger does way more.

Customers save up to 20% on shipping and operations when shipping garments on Ditto Hangers. 20% off all shipping, loading, unloading, and storage space in crowded distribution centers. In addition, for every 4 containers, the 5th is free.

The Ditto Hanger fits up to 50% more garments on retail display racks, which means more selection for consumers and less time for floor staff to swap out stock. More stock and more staff time with customers equals more sales. The bottom line: more sales per retail square foot.

The Ditto Hanger offers 100% more marketing and branding add-ons than a one-function plastic hanger. The Ditto Hanger uses color-coded hangers for sales or special seasonal promotions. In addition, it has multiple post-sales benefits, such as QR codes for building brand loyalty.

The Ditto Hanger is 100% more sustainable. It's made from 100% recycled material and is 100% non-toxic. It is 100% recyclable at the store level with cardboard boxes and recyclable in consumers' curbside recycling program.

One ton of hangers produced in a Life Cycle Assessment ("LCA") shows that Ditto Hangers emitted less CO2, about 1,606 kg, than wood, 2,540 kg, recycled plastic, 1,904 kg, and virgin plastic hangers, 2,721 kg. The same LCA showed that the Ditto Hangers used considerably less oil, 4.23 barrels, than virgin plastic, 19 barrels, and wood hangers, 16 barrels. The Ditto Hangers used much less water to process, 2,300 gallons, than virgin plastic, 44,000 gallons, recycled plastic, 43,800 gallons, wood hangers, 21,725 gallons to process and 1,240 gallons to grow. Finally, the Ditto Hangers used 22M BTU energy to process, compared to recycled plastic, 23M BTU, and virgin plastic, 121M BTU.

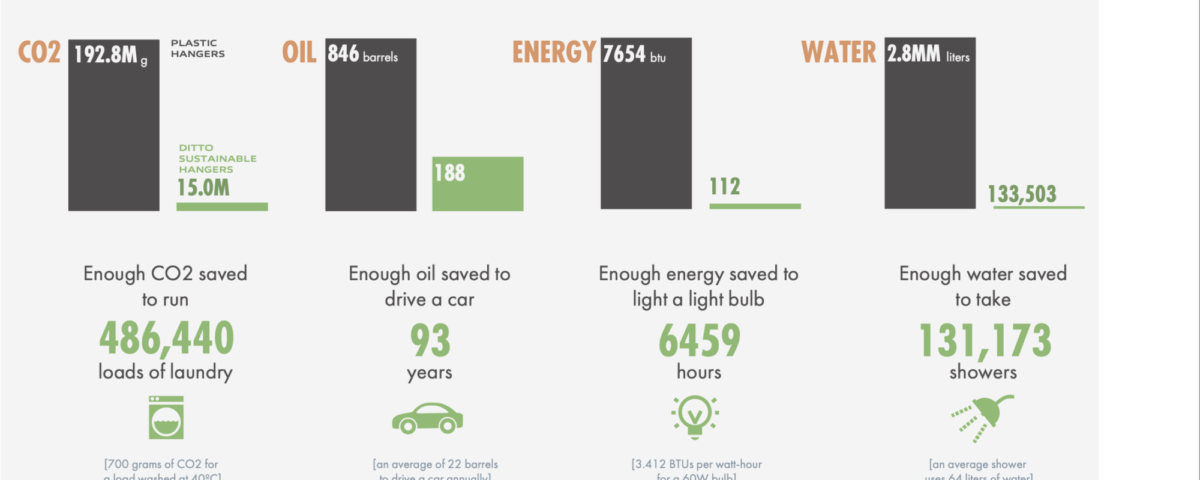

A customer switch to a 5 million unit Ditto Hanger program would significantly impact the environment and society. The switch would save enough CO2 to run 486,440 loads of laundry, enough oil to drive a car for 93 years, enough energy to light a light bulb for 6,459 hours, and enough water to take 131,173 showers.

Get stories of positive business innovations from around the world delivered right to your inbox.

Gary Barker, CEO and founder, Director of Sustainability