Keep this story going! Share below!

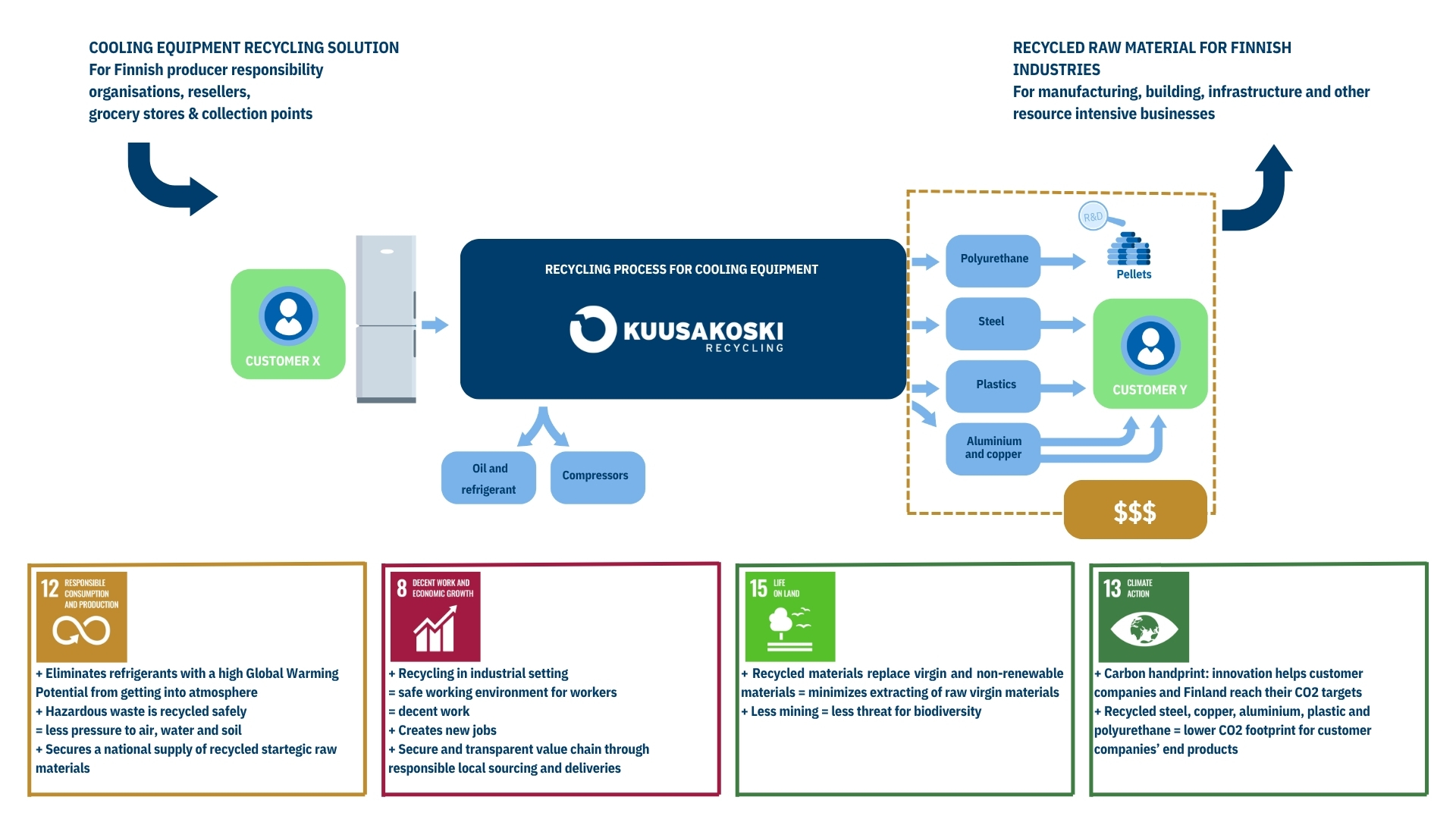

Kuusakoski Oy has built a new recycling plant in Hyvinkää, Finland, in 2024 to process discarded cooling equipment. This innovation enables the recycling of metals, plastics and polyurethane from appliances while safely handling hazardous materials such as refrigerants and oils. In addition to supporting environmental sustainability, the innovation offers new jobs locally and strengthens Kuusakoski’s business and role as a circular economy pioneer, as recycling solutions are critical enablers of circular economy.

Cooling appliances like freezers and refrigerators are one of the most challenging waste streams in electronics recycling. They contain gasses and oils, which are flammable materials, in addition to a complex mix metals, plastics and polyurethane. The Kuusakoski plant in Hyvinkää provides an extremely advanced system, which dismantles appliances safely, recovers useful raw materials for reuse, and reclaims toxic refrigerants are used as energy or reused.

The system is built to maximize material recovery rates. Steel is extracted for use in heavy industry, copper is refined further for customers such as Boliden, and aluminum is delivered to manufacturers seeking low-carbon raw materials. Plastics are sorted into recyclable polymers with specialized recycling partners, while polyurethane insulation is pelletized and repurposed in applications like the cement industry or used as energy.

What makes this solution innovative is not only the technical sophistication of handling hazardous and flammable substances but also the way that multiple material recovery streams are combined in one facility in a cost-effective way. By doing so, Kuusakoski ensures that nearly all the material in the discarded appliances can be put back into circulation. As Tapio Kuusakoski, WEEE Business Director from Kuusakoski highlighted in the interview, “There’s a saying that if you can master recycling cooling equipment, you can master recycling any electronics.” Additionally, the plant’s scale is remarkable: it is capable of handling the recycling needs of all cooling equipment in Finland.

Previously, some refrigerators had to be shipped to Sweden because Finland’s only other facility lacked sufficient capacity. Bringing this innovation to life therefore demanded not only technical expertise and creativity, but also considerable courage from the leadership to commit to such a substantial investment.

According to Tapio Kuusakoski, the inspiration for this innovation started from discussions with the customer who needed to get rid of cooling equipment. They needed better and more cost-effective solutions. This indicated that the demand was already there.

In addition, the customer base and demand for the raw materials created from the recycling process already existed as Kuusakoski has a long history in the business, and the demand for high quality recycled materials is constantly growing. This is partly due to regulation put in place by the European Union and by the needs of customers that aim to cut their CO2 emissions.

Recycled materials need to be high quality to be used as raw materials in the existing processes in other companies. Kuusakoski both invests in research and development and collaborates closely with their customers, at both ends of the value chain, to ensure the right quality of materials.What was missing was a safe, sustainable and efficient process to transform decommissioned cooling equipment and turn them into valuable raw materials for reuse. To achieve this, Kuusakoski combined different technologies in a new innovative way.

Innovation is a constant learning process. It is still evolving as new challenges are solved when they emerge: “Solutions develop as they are operated – the real innovation is yet to come”, Tapio Kuusakoski described.

Kuusakoski Oy solves the end-of-life challenge for the cooling equipment manufacturers, who in the EU have an obligation by the Extended Producer Responsibility to take care of the recycling and disposal of their products. Kuusakoski’s new recycling plant processes discarded cooling appliances efficiently and safely.

The innovation plays an important role in the transformation towards circular economy. By being “the last bit of the loop”, Kuusakoski keeps valuable materials in circulation and closes the loop.

The short-term impacts of the innovation include decreasing transportation emissions by up to 60%, since cooling equipment no longer needs to be shipped abroad for treatment, and creating new local jobs in a working environment, where safety is a priority.

In the long run, the environmental benefits are impressive:

This recycling innovation solves problems for the producers of cooling equipment who need to ensure proper disposal of their products. Kuusakoski’s plant in Hyvinkää provides these manufacturers a reliable and cost-effective way to meet their obligations, while also ensuring the responsible treatment of discarded appliances.

The demand for recycled materials is constantly growing. The new capacity to recycle cooling equipment creates an additional incoming material stream for Kuusakoski to transform into high quality materials, which can then be sold to industries/businesses wanting to minimize virgin materials in their products. The high demand and price for recycled raw materials make recycling a profitable business, also contributing to economic growth.This creates both new service and revenue streams for Kuusakoski and strengthens its role as a pioneer in the circular economy.

The solution has both direct and indirect societal and environmental benefits and supports several UN sustainable development goals. Decent Work and Economic Growth (SDG 8) is supported by creating new jobs locally in a safe working environment. The high demand and price for raw materials make recycling a profitable business, contributing to economic growth.

By offering a recycling process that supports environmental sustainability, especially SDGs Climate Action (SDG 13) and Life on Land (SDG 15), Kuusakoski helps vendors and Finnish consumers on their path to Responsible Consumption and Production (SDG 12). The direct environmental benefits of this innovation are brought about by eliminating waste, circulating materials and enabling circular economy. Eliminating waste reduces pollution, and pressure on biodiversity and the climate. Recovering and safely processing harmful substances, such as refrigerants, helps to avoid greenhouse gas emissions and pollution. Using recycled raw materials instead of virgin materials decreases the need for resource extraction. Mining metals, for example, is energy-intensive and can damage ecosystems, local communities and landscapes.

The innovation also brings about indirect social benefits. Avoiding the release of harmful substances and focusing on safer methods of recycling - translating into less hazards for individuals and society in the big picture.By enabling circular transition and acting as a major driver in closing the material flow loop the innovation and investment made by Kuusakoski in 2024 supports the development of a healthier and more sustainable society.

Get stories of positive business innovations from around the world delivered right to your inbox.

Tapio Kuusakoski, WEEE Business Director

Kuusakoski Oy is a Finnish industrial recycling company founded in 1914. The company provides recycling services and innovations with an international track record. As stated in their mission, they want to restore the value of waste materials by processing them into new valuable raw materials and play a key role in advancing circular economy in Finland and globally.