Keep this story going! Share below!

Each year, about 1 billion tires reach the end of their life. Thanks to this recycling technology, tires that have been used are transformed to give birth to new quality raw materials.

Modifying the chemical composition and physical aspect of the pneumatic material during the pyrolysis process, will guarantee a minimal energy consumption.

This highly innovative technology enables production of high-quality products such as recovered carbon black, pyrolysis oil, steel or gas. Products that can then be re-incorporated into the production circuit of different industrial sectors. Thanks to this recycling technology, tires that were considered a pure waste, will now be recycled into new raw materials.

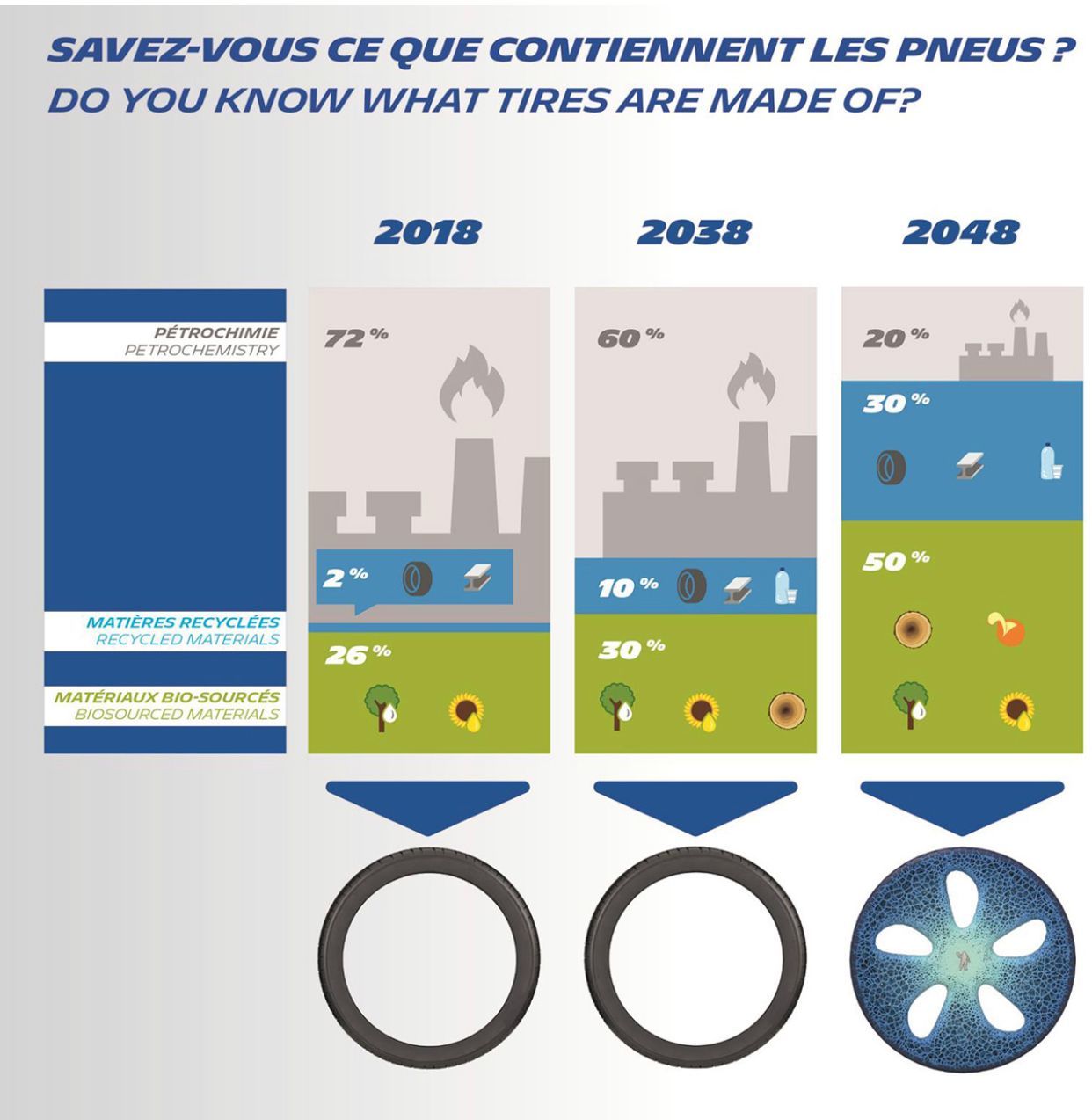

The result of this innovation is producing a 100% sustainable tire.

Natural rubbing, which is the main technique for the ingredients in a tire, in the production phase are what define innovation. Tires also contain more than 200 other ingredients that are helpful to produce a tire of quality, and have a high environmental impact. These include synthetic resins and silica.

The company will present specific plans to phase out and replace unsustainable materials in the near future.

Michelin will change the supply chain and material design.

They will replace petroleum-derived butadiene through a process that includes wood, rice husks, leaves, corn stalks, and other plant debris.

Also produce recycled styrene from plastics found in commercial product packaging.

Finally include the disintegration of PET plastic.

Inspired by the VISION concept tire introduced in 2017, an airless, connected, rechargeable and entirely sustainable solution:

100% Sustainable means: disruptive innovation with biological sources and origins, as well as the use of recycled materials.

VISION leverages the high-tech materials expertise of Michelin and its partners to achieve the objective of 100% sustainable materials by 2050.

The tire’s lifecycle ensures that its environmental footprint is minimal.

The total yearly saving is equivalent to 33 millions of barrels of oil or equal to the energy consumption for a month of all of France.

For the year 2038, the objective would be of 75% recyclable product, with a 10% energy consumption savings.

For the year 2048, a 100% in recyclable products.

70% of the main 400 hundred suppliers will reach Michelin´s environmental standards.

Promote responsible logistic and reduce by 10% Michelin´s CO2 emissions.

Reduce Michelin´s environmental print by 50%.

Michelin will become a benchmark brand within the industry for its sustainable and responsible focus.

Long-term performance, as a stand against planned obsolescence. Not only has it become vital to work on sustainable mobility, it is just as important to guarantee that Michelin's customers benefit from all Michelin's engineering and expertise throughout the life cycle of the products they offer.

Through the creation of 100% sustainable tires by the year 2048, this will have an impact in society due to the recycling programs that are currently encouraged. In addition, this will improve the slipping performance of the tire that will also generate minor CO2 and carbon footprint.

This will have an impact in all types of markets, but also Michelin will produce a circular economy, taking advantage in every step of the process because this benefit will have an effect in it´s suppliers, and customers available all over the world.

The development of sustainable materials, incorporated into an efficient tire technology has showed to be able to reduce the fuel consumption (tires that represent between 20% to 30% of vehicle consumption). This decrease on fuel consumption contributes to the decrease in greenhouse gas emissions and the carbon footprint. This being said, respiratory health will improve because all air-pollution related diseases will decrease in humans, and also ecological processes affected by carbon emissions and raw materials will have a positive effect on them. Finally, driving in these conditions is going to be safer because the tire will adapt to different road conditions, such as off- road, rain or snow.

Get stories of positive business innovations from around the world delivered right to your inbox.

Producing tires by adapting the constant customer and employee expectations; to improve customer satisfaction, empowering teams and accelerating the group’s digitalization. All of this considering the green energies, stimulating collective intelligence and the liberty to maneuver which is essential in the world it operates.