Keep this story going! Share below!

Nitto Belgium, located in Genk and part of the globally operating Nitto Group (Japan), is a leading manufacturer of functional films, tapes, and industrial adhesive solutions used across sectors such as automotive, electronics, construction, and healthcare. With over a century of expertise and more than two decades of Belgian operations, the company combines technological excellence with a strong focus on sustainability.

Over the past years, Nitto Belgium has embedded circular product innovation into its business strategy. The company develops eco-designed adhesive and film technologies using recycled and bio-based materials to minimize CO₂ emissions and reduce resource dependence. These materials are used across various industries, enabling clients to achieve their sustainability targets.

Through this innovation, Nitto demonstrates that industrial production can be both profitable and environmentally responsible. By integrating sustainability principles from product design to manufacturing, the company contributes directly to the United Nations Sustainable Development Goals (SDG 9 – Industry, Innovation & Infrastructure; SDG 12 – Responsible Consumption & Production; and SDG 13 – Climate Action).

Nitto Belgium has embedded sustainability within its core innovation process. Every new product begins with a stage-gate development model in which sustainability is assessed from the earliest concept phase. As Sustainability Manager, Ingrid Wasbauer explained, “We look at product development already from the concept phase — how much recycled material can be used, how energy-efficient the process will be, and how the product can reduce waste for the customer.”

This proactive method ensures that every innovation supports the company’s long-term Science-Based Targets for CO₂ reduction. The company distinguishes between Planet Flag and Human Flag products — a framework for identifying products that generate measurable value for the environment (Planet Flag) or for society (Human Flag).

For instance, Nitto has developed anti-reflective automotive films and biodegradable materials for personal care products, reducing waste and energy consumption. These sustainable products are co-created with clients to ensure economic feasibility and industrial scalability.

By tracking Key Performance Indicators (KPIs) related to carbon emissions, recycling ratios, and circularity, Nitto integrates sustainability into decision-making at every level. As Wasbauer summarized, “We make sure sustainability is not a separate department — it’s part of how we innovate, produce, and sell.”

Nitto’s transition toward circular product development is driven by both external regulation and internal conviction. The European Green Deal acted as a key accelerator, pushing companies to comply with strict environmental reporting and emission targets. However, the deeper motivation lies in the company’s culture of continuous innovation.

Wasbauer reflected on this evolution: “We were already phasing out harmful chemicals for safety reasons, but the Green Deal really accelerated the move toward sustainability and compliance reporting.”

As a Japanese multinational, Nitto’s global identity emphasizes innovation seekers — companies that innovate not only for profit but also for long-term value creation. Within the Belgian operations, this philosophy translated into a holistic approach involving every department. Procurement screens for sustainable materials, R&D focuses on circular design, production improves energy efficiency, and sales teams work with customers to promote sustainable solutions.

This collective mindset ensures that sustainability is embedded in the business rather than treated as charity or philanthropy. “Sustainability sits everywhere,” Wasbauer explained. “Everyone can contribute — from R&D to the factory floor.”

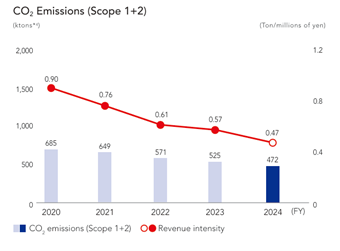

The impact of Nitto Belgium’s innovation is evident across environmental, social, and business dimensions. On the environmental side, the company has achieved year-over-year reductions in Scope 1 and 2 CO₂ emissions and set a target for carbon neutrality by 2045, five years ahead of the Paris Agreement deadline. The company has already done a great job reducing CO₂ emissions in scopes 1 and 2 between 2020 and 2024, reducing them from 685.000 tons to 472.000 tons.

Socially, Nitto encourages employees to actively contribute to sustainable development. Through the Gate Competition, employees can propose environmental or safety improvements, with winners advancing to regional and even global competitions in Japan. This bottom-up approach strengthens engagement and spreads environmental awareness throughout the organization.

Nitto’s achievements have also been recognized externally. The company holds Platinum and Gold Ecovadis certifications, placing Nitto Belgium among the top 5% of sustainable industrial firms in Europe. Wasbauer proudly shared, “We work with Ecovadis and received Platinum for Nitto Belgium. That means we belong to the top 1–5% in comparable industries in Europe.”

This recognition underscores the global impact of Nitto’s local innovation efforts, inspiring similar initiatives across the Nitto Group worldwide.

Integrating circular innovation has yielded significant strategic and financial advantages for Nitto Belgium. The company’s focus on resource efficiency and waste reduction has lowered operational costs and increased profit margins. “There have been significant investments in ESG,” Wasbauer explained, “but so far every one of them has had a return on investment.”

The innovation also strengthens customer loyalty. Many clients now prefer to work with suppliers that align with their sustainability targets. Wasbauer emphasized this point: “Many of our customers highly value our ESG focus. It strengthens relationships and makes them come back to us again.”

Furthermore, Nitto’s reputation as a sustainability leader has opened doors to new markets, such as renewable energy (e.g., solar panel components) and eco-efficient automotive materials. The company also benefits from governmental subsidies for sustainable investments, reinforcing the financial viability of its green transition.

In sum, Nitto’s circular model transforms sustainability from a cost factor into a competitive advantage, aligning profit with purpose.

Beyond business gains, Nitto Belgium’s innovation delivers tangible benefits for society and the planet. The company’s use of recycled and bio-based materials helps reduce dependence on fossil resources, while its energy-efficient designs contribute to overall emission reduction.

Examples include energy-saving refrigerator coatings, eco-friendly filters that reduce energy consumption in appliances, and biodegradable wet wipes produced for major personal care clients. Each of these innovations helps minimize waste and enhance environmental performance throughout the value chain. Nitto has also succeeded in lowering the energy required for its production processes: in 2021, the company consumed 2.113.800 MWh of energy, and by 2024, this had decreased to 2.098.776 MWh. Although the reduction may appear modest, it still represents meaningful progress toward Nitto’s commitment to protecting the planet and achieving a decarbonized society.

In addition, Nitto’s collaborative approach extends to cross-sector partnerships and knowledge sharing. Wasbauer highlighted one such initiative: “We once explored a closed-loop system where we would collect our customers’ waste and reuse it as raw material. It wasn’t viable for us alone, but if organized with multiple partners, it could succeed.”

Through cooperation, transparency, and innovation, Nitto Belgium exemplifies how industrial companies can create net positive impact — simultaneously contributing to economic prosperity, a healthier environment, and improved human well-being.

Get stories of positive business innovations from around the world delivered right to your inbox.

Ingrid Wasbauer, Sustainability Manager