Keep this story going! Share below!

Scania’s innovation focuses on accelerating the transition to sustainable transport through the electrification of trucks, renewable energy use, and circular production processes. By integrating battery technology, green logistics, and responsible resource management, Scania aims to achieve net-zero emissions by 2030. These efforts contribute to four UN SDGs:

SDG 7 – Affordable and Clean Energy

SDG 9 – Industry, Innovation and Infrastructure

SDG 12 – Responsible Consumption and Production

SDG 13 – Climate Action

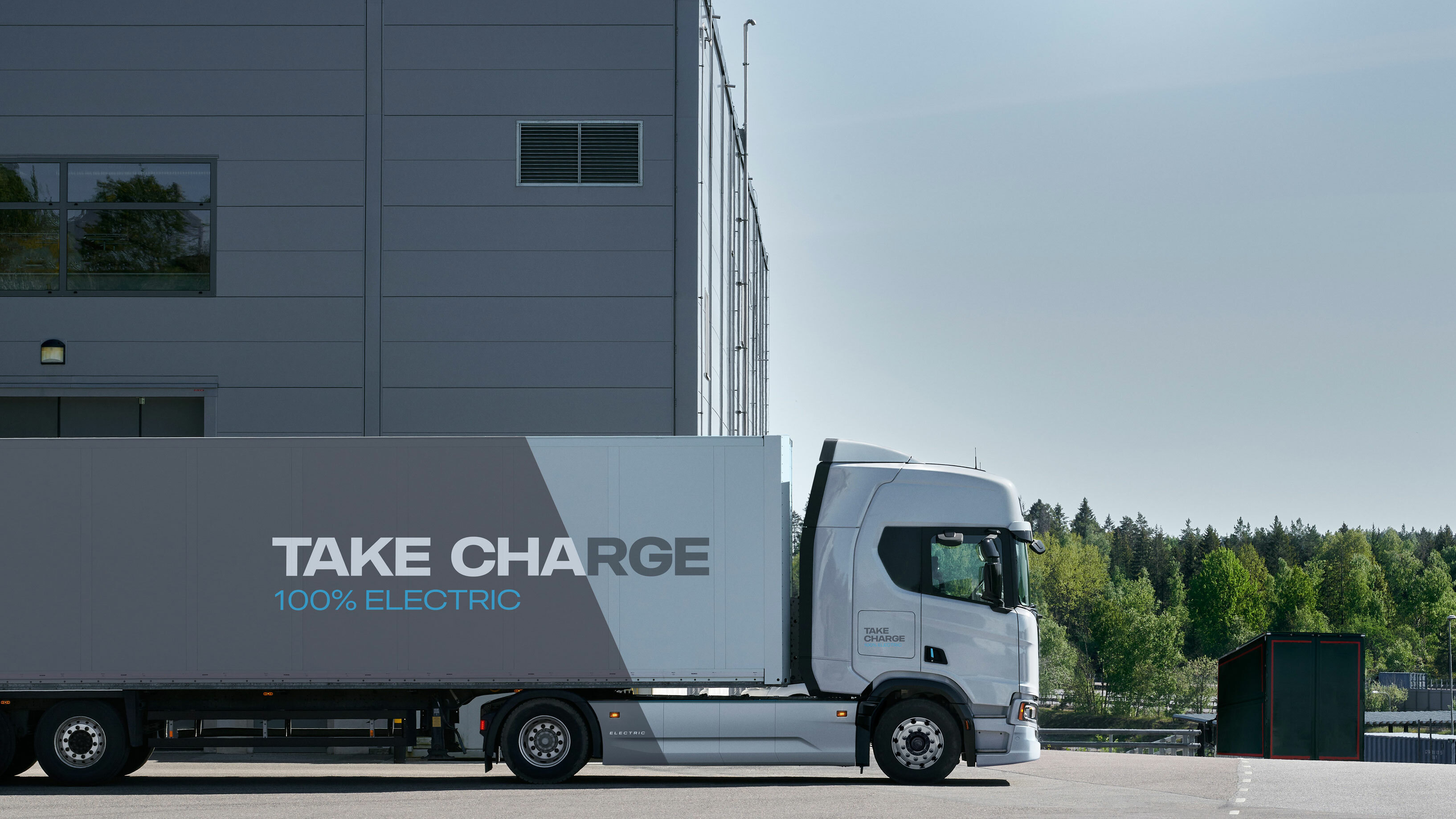

The innovation of Scania is centered on the transformation of the heavy transport industry through the introduction of battery-electric trucks (BEVs) and a broader commitment to carbon neutrality by 2030. This shift represents not just a technological advancement but a systematic change in how transport, logistics, and production are approached within the company. The initiative combines electrification with sustainable manufacturing processes, renewable energy use, and circular economy principles, positioning Scania as a global leader in sustainable mobility.

Founded over a century ago, Scania has continuously evolved through innovation. However the current transition is one of its most ambitious yet. The company’s Integrated Electrification Model encompasses the entire value chain. From design and production to logistics and aftersales, the model ensures that sustainability is embedded in every step.

This integrated model relies on technological innovation, strategic partnerships, and organizational learning. Initially, Scania collaborated with Northvolt, a Swedish battery manufacturer using recycled materials from former mining sites, to source environmentally responsible batteries. After Northvolt’s bankruptcy, Scania quickly adapted, forming new partnerships to ensure production continuity. Nilsson, Warehouse Director at Scania Parts Logistics, highlighted this flexibility as a strength of the company’s innovation culture:

“We might face challenges with suppliers or costs, but we adapt quickly. Innovation comes down to learning and improving on a daily basis.

At the same time, Scania invests in green energy infrastructure for its production sites, refurbishment programs for parts, and research to improve vehicle range, charging speed, and performance. The Parts Logistics Division in Oudsbergen has taken tangible steps toward sustainability through renewable energy, waste reduction, and circular material flows. As Nilsson noted: “It’s not just the truck; it’s the whole chain. We also focus on our buildings and our production, so that everything contributes to being CO₂ neutral.”

Within just a few years, Scania’s sustainability efforts have already achieved an estimated 20% reduction in CO₂ emissions, marking substantial progress toward its carbon-neutral goal.

The inspiration behind Scania’s innovation came from the realization that the future of transport must be electric, not merely as a response to trends, but as a responsibility. They already have a leading role in the truck sector and the next logical move was to position themselves as a driver of sustainable development. Nilsson explained that external factors, such as European environmental regulations and growing customer demand for clean transport, accelerated this transition. However, the company’s internal conviction was equally strong.

The roots of this transformation lie in Scania’s longstanding culture of responsibility and continuous improvement. When faced with the challenge of redefining its business model, Scania’s leadership made a bold decision to lead the change rather than follow it.

This mindset has turned sustainability into a strategic priority across the company. It is no longer a separate department but an integrated value guiding every operational decision. As Nilsson put it:

“Sustainability is very high in our strategy. Even if it means higher costs or longer lead times.”

This statement highlights Scania’s willingness to prioritize ethical and environmental goals over short-term economic gain, an approach that differentiates it from more profit-driven competitors.

In essence, Scania’s inspiration grew from a moral, environmental, and business necessity, to build a transport system that protects both people and the planet while ensuring long-term competitiveness.

The impact of Scania’s innovation extends far beyond technology; it is reshaping the company’s culture, brand, and contribution to society. The transition to electric mobility represents a holistic transformation, influencing not only what Scania produces but also how it thinks, operates, and collaborates.

“Sustainability really seeps through, it goes from top to bottom,” Nilsson shared.

The results are already visible. The company’s CO₂ emissions have dropped by 20% in three years, and the introduction of electric trucks is transforming logistics networks across Europe. Scania’s circular economy initiatives, such as reusing and recycling components, further reduce environmental impact while generating economic value.

On the social front, this innovation contributes to cleaner air, safer communities, and healthier living environments, especially in urban areas where heavy transport is a major polluter. The company’s partnerships with competitors like Volvo and Daimler to build a continent-wide charging infrastructure show that sustainability is not a competition but a shared mission.

Scania’s model demonstrates that environmental responsibility and industrial growth can coexist, creating a blueprint for other transport companies aiming for sustainable transformation.

Scania’s sustainability journey has strengthened its market position, brand value, and long-term profitability. The company’s focus on electrification has allowed it to position itself as a premium, sustainable transport brand, attracting new customers, investors, and partnerships.

In 2024, Scania sold 6,558 vehicles powered by alternative fuels and electricity, representing 6% of total vehicle sales. This demonstrates a direct growth market driven by increasing demand for sustainable transport solutions. Scania has also strengthened its position in key regions, capturing additional market share in Europe and Latin America; in the EU27, its share in heavy trucks (>16 tons) increased to 17.8% (from 15.4% in 2023). To accelerate this transition, Scania has launched several innovative initiatives and partnerships.

JUNA, a joint venture, gives small and medium-sized transport operators access to electric trucks through a pay-per-use model, lowering financial and operational barriers. Additionally, Einfrast, a newly established charging company, aims to install 40,000 new charging points across Europe by 2030, significantly expanding charging infrastructure and customer accessibility.

These initiatives reinforce Scania’s market position and differentiation. Winning prestigious awards such as the Green Truck Award 2024 (for the seventh time in eight years) and the Sustainable Bus Award 2025 further strengthens its premium positioning and appeal to customers prioritizing sustainability.

Nilsson acknowledged that the transition comes with significant challenges. These trucks cost two to three times more than conventional models with a shorter range. The challenge is to put a product on the market that is cheaper than the current one. To tackle this, Scania focuses on life-cycle value rather than upfront price by emphasizing total cost of ownership and long-term fuel savings for clients.

Scania’s focus on circularity and elimination of waste in production has also led to operational efficiency gains and cost savings, enhancing financial resilience. Despite these challenges, Scania’s strategic alliances, technological innovation, and integration within the Volkswagen Group provide both financial stability and scalability. The company’s collaboration with major industry players also expands opportunities for shared infrastructures and knowledge exchange, leading to long-term competitive advantage.

Internally, Scania’s sustainability strategy has boosted employee engagement and pride. The company’s inclusive culture, supported by its “Skill Capture Model” and clear purpose “Drive the shift”, is cited as crucial for attracting and retaining talent. In 2024, Scania’s workforce increased slightly from 58,163 to 58,845 employees, reflecting its ongoing growth and appeal as an employer. Teams across departments are united by a shared purpose: driving the shift toward sustainable transport. This collective commitment fosters innovation, retention, and a strong sense of meaning at work.

Scania’s innovation directly contributes to multiple social and environmental outcomes aligned with the UN Sustainable Development Goals.

Environmentally, the move toward electric trucks and renewable energy in production drastically cuts greenhouse gas emissions and air pollutants. The company’s circular initiatives, such as refurbishing parts and recycling materials, support SDG 12 (Responsible Consumption and Production), while the electrification of fleets supports SDG 13 (Climate Action).

A cornerstone of Scania’s circular business model is refurbishing (remanufacturing), which aims to maximizing product lifespans and minimizing waste. The company tracks its progress through a dedicated circularity KPI that the amount of non-recycled waste per vehicle produced. In 2024, this figure increased to 426 kg per vehicle, mainly due to construction and renovation activities, but Scania maintains its ambition of achieving a 50% reduction between 2015 and 2025. This underlines the company’s strong commitment to reusing and recycling materials as part of its sustainability strategy. Beyond production, Scania’s electric truck logistics are now deployed in over 30 European cities, significantly reducing urban CO₂ and noise emissions.

“It’s not just about building electric trucks; it’s about building a culture where people learn, adapt, and find real purpose in their work.”

Socially, Scania’s transformation benefits employees and communities. Cleaner logistics mean healthier cities, aligning with SDG 3 (Good Health and Well-Being). Partnerships with municipalities and educational programs promote green skills and environmental awareness, advancing SDG 4 (Quality Education) and SDG 8 (Decent Work and Economic Growth). In 2024 alone, Scania collaborated with 15 municipalities and 10 vocational schools, training more than 2,000 students and drivers in sustainable transport technologies.

Through this innovation, Scania demonstrates that even industries traditionally built around fossil fuels and emissions, such as transport and logistics, can successfully transition toward sustainability through innovation and commitment. It also demonstrates that sustainability can be a source of competitive strength, social progress, and environmental protection, proving that a cleaner and smarter transport industry is not only possible but essential.

Get stories of positive business innovations from around the world delivered right to your inbox.

Anders Nilsson, Warehouse Director

/, /

Scania is a Swedish company that designs and manufactures heavy trucks, buses, and industrial and marine engines. It focuses on providing efficient, sustainable transport solutions for logistics, public transport, and industrial operations. The company also offers services such as maintenance, financing, and fleet management to support customers throughout a vehicle’s lifecycle. Scania is known for its emphasis on fuel efficiency, modular manufacturing, and low-emission technologies. Its global operations help drive innovation in sustainable mobility and commercial transportation.