Keep this story going! Share below!

Concrete is everywhere; it is used to build our roads, schools, hospitals, and water systems. In fact, concrete is the most abundant human-made material in the world (CarbonCure's eBook). The widespread use of concrete is a testament to its efficacy, and it is expected to be used increasingly as population growth and urbanization trends result in more densely populated cities (CarbonCure's eBook). However, there is one major problem. Concrete production is one of the largest industrial emitters of carbon dioxide (CO2) and is a major contributor to the global climate crisis (CarbonCure's eBook). There is, thus, an urgent need for greener concrete. At the forefront of such innovation is CarbonCure Technologies Inc. (CarbonCure), a company that specializes in carbon dioxide removal technologies for the concrete sector.

With an ambitious mission to reduce 500 megatonnes (Mt) of CO2 from the built environment annually by 2030, CarbonCure’s strategy is to create retrofit solutions for the concrete industry with very low barriers to adoption (CarbonCure's eBook). According to CarbonCure’s CEO & Founder, Robert Niven, these types of technologies are necessary to meet the goals set forth by the Paris Climate Agreement.

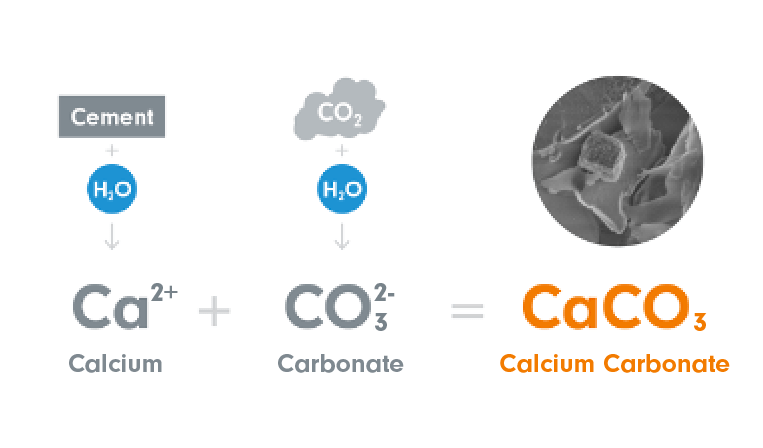

The company’s core technology is called CarbonCure for Ready Mix, which is a retrofit technology for concrete producers that injects recycled CO2 into concrete during the mixing process. Once injected, the CO2 reacts with calcium ions in cement, the key ingredient that gives concrete its strength, thereby forming calcium carbonate (CaCO3). This process not only permanently captures CO2, but it also increases the strength of concrete, enabling concrete producers to use less cement, further reducing concrete’s carbon footprint. The company’s CarbonCure for Ready Mix technology is currently being used at approximately 300 concrete plants, mostly in the United States and Canada.

If the company wants to achieve its goal of reducing 500 Mt of CO2 annually by 2030, Niven recognizes that CarbonCure for Ready Mix, alone, will not be enough. According to Niven, it will require the company to “bring a new portfolio of science and technologies from our lab and into the real world.” To this end, CarbonCure is currently in the process of developing two new technologies to add to its portfolio: CarbonCure for Reclaimed Water and CarbonCure for Recycled Aggregate. CarbonCure’s growing portfolio of technologies will further reduce the carbon footprint of concrete and will simultaneously increase profitability, quality, and resource circularity for concrete producers (CarbonCure's eBook). CarbonCure has also developed a suite of digital solutions, offered through the myCarbonCure portal, that leverages the power of data to accelerate the adoption of CarbonCure's technologies and increase customer satisfaction (CarbonCure's eBook).

The inspiration for CarbonCure’s core technology arose when Niven was pursuing a master’s degree in civil engineering at McGill University in Montreal, Quebec. At McGill, research was already being conducted in the domain of CO2 and concrete. In fact, according to Niven, “People had been looking at this space for decades.” However, Niven attributes his innovative idea to the unique perspective gained from having completed a bachelor’s degree in chemistry. In Niven’s words, “Technology was being developed in the hands of engineers when it might have required the perspective of a chemist.” This research became the focus of Niven’s master’s thesis.

Concurrent with his research at McGill, Niven was inspired by the United Nations (UN) climate change talks that were taking place in Montreal at the Conference of the Parties 11 (COP 11) in 2005. As Niven puts it, "I was armed with technology and knowledge, a little bit of naivety. Definitely, the fire was lit on being able to do something for people. Helping people out. And then business is actually pretty simple. It's just logic and empathy, you put all that together in a pot and stir it, and with a bit of luck, you end up where we are today.”

By 2060, the world is expected to add 230 billion square metres of new buildings, which is the equivalent of another New York City being built every month for the next 40 years (CarbonCure's eBook). According to Niven, “We’re going to need a lot of concrete to keep up with population growth and urbanization.” Despite concrete’s high carbon footprint, there is no credible alternative to concrete due to its strength, durability, and resilience in construction (CarbonCure's eBook). In Niven’s words, “Concrete is required, we just need to do it more resource efficiently, and using less cement is an economic driver in that process.” By adopting CarbonCure for Ready Mix, concrete producers can reduce their environmental footprint while simultaneously benefiting financially. According to the company, “What is currently viewed as a threat to the industry may just be one of its greatest opportunities” (CarbonCure's eBook). By seizing this opportunity, CarbonCure is contributing greatly to the achievement of Sustainable Development Goal (SDG) 9: To build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation, SDG 11: To make cities and human settlements inclusive, safe, resilient, and sustainable, and SDG 13: Take urgent action to combat climate change and its impacts.

CarbonCure’s vision is that the decarbonization of concrete and profitability are not mutually exclusive. In fact, according to Niven, “One of the main reasons why we’ve been able to scale-up so quickly where others that are operating a similar technology domain have been stagnant at pilot level is due to the financial drivers of the business that are complemented by the environmental benefits.”

There are three economic incentives for concrete producers that drive CarbonCure’s growth. Firstly, concrete producers that adopt CarbonCure’s technology reduce their costs through cement savings. As was previously mentioned, the injection of CO2 into concrete increases its strength. This allows concrete producers to achieve up to a 7% reduction of cement, which is the most expensive ingredient in concrete (CarbonCure's website). Secondly, concrete producers financially benefit through sales differentiation. As stated by Niven, “Concrete producers have a greener product which is in high demand in the marketplace, so this allows them to gain more market share.” This is particularly important in a commodity-based industry. Finally, financial drivers also come in the form of carbon offsets. A carbon offset is a financial instrument that represents a tonne of CO2 removed or reduced from the atmosphere and is purchased by companies that want to compensate for emissions made elsewhere (Carbon Offset Guide). CarbonCure’s first carbon offset buyer was tech giant, Stripe, which purchased carbon offsets from CarbonCure in May 2020. Niven describes CarbonCure’s carbon offset business as a “virtuous circle” for both CarbonCure and concrete producers using the company’s technology. According to Niven “As they create more [concrete], then it creates more credits and as long as they are our buyers, this cycle continues to drive growth and deployment of clean solutions and helps us get to that 500 megatonne goal.” The revenue from carbon offsets is shared between CarbonCure and its concrete producing partners.

When concrete producers economically benefit from CarbonCure’s technology, so does CarbonCure, as the company’s revenue is largely derived from monthly technology licensing fees. According to Niven, “There are two ways to do business. You can either walk on people and that’s always a short-term gain and there is always a reckoning, or you can find alignment…It’s about trying to find win-win solutions.” It is through the development and deployment of win-win solutions that CarbonCure is building a prosperous business. Billionaire investor and philanthropist, Bill Gates, agrees with this notion and has made a significant investment in CarbonCure through his Breakthrough Energy Ventures (BEV) fund. In a February 15, 2021 interview on CBS 60 Minutes, Gates highlighted CarbonCure as a company that exemplifies BEV’s stated goal to “Build the new, cutting-edge companies that will lead the world to net-zero emissions.”

The International Panel on Climate Change (IPCC) states that a global temperature rise of 1.5 °C above pre-industrial levels would result in irreversible and catastrophic climate change impacts (CarbonCure's eBook). According to Niven, if CarbonCure is able to achieve its mission of reducing 500 Mt of CO2 annually by 2030, that will account for “a significant portion of the GHG emission reductions that need to occur to keep within a 1.5 °C climate target.” To provide some insight into the magnitude of CarbonCure’s possible environmental impact, a reduction of 500 Mt of CO2 is the equivalent of taking 100 million cars off the road (CarbonCure's eBook).

However, if CarbonCure wants to achieve this ambitious goal, the company needs to act urgently, not just because the climate threshold is drawing near, but also because every time concrete is poured without CarbonCure for Ready Mix, this represents a missed opportunity to remove CO2 from the atmosphere and sequester it into concrete. Because the vast majority of concrete is being poured in developing countries, CarbonCure is planning to expand rapidly into those markets. According to Niven, “Places like South America, Asia, Africa, India and subcontinent are really where the demand is and where the climate impacts are most sensitively felt.”

The environmental benefit created by CarbonCure is not just a thing of the future. To date, CarbonCure has already saved 106,154.8 tonnes of CO2 emissions, and that number is growing every day (CarbonCure's website).

Get stories of positive business innovations from around the world delivered right to your inbox.

Robert Niven, CEO & Founder

CarbonCure Technologies Inc. (CarbonCure) is a clean technology company that is working towards decarbonizing the concrete industry. With an ambitious mission to reduce 500 megatonnes of CO2 annually by 2030, CarbonCure is a company that is making significant strides towards more a more sustainable world.